Dutch UV manufacturer bestUV is again selected to deliver Önorm validated BetaLine UV systems for two scandinavian communal drinking water plants. The drinking water is mechanical filtered surface water and origins from the lake. The two waterworks decided to replace some low-pressure (LP) UV systems, installed in the 80‘s, by ‘state-of-the-art’ bestUV systems.

Dutch UV manufacturer bestUV is again selected to deliver Önorm validated BetaLine UV systems for two scandinavian communal drinking water plants. The drinking water is mechanical filtered surface water and origins from the lake. The two waterworks decided to replace some low-pressure (LP) UV systems, installed in the 80‘s, by ‘state-of-the-art’ bestUV systems.

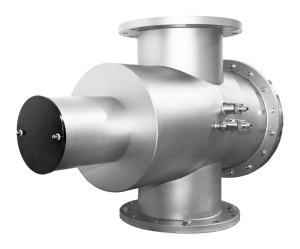

BetaLine UV systems were introduced to the market after intense validation procedures at universities for Water hygiene, (Patho)physiology and Biophysics. They are approved by several international health institutes for use in disinfection of water for human consumption.

BetaLine is a compact UV system, equipped with unique high-efficient low-pressure UV lamps. They operate in automatic mode on the most economic lamp power due to bestUV’s intelligent power controlsystem. The bestUV system runs exactly on the power needed to fulfill minimum UV dose requirements, even when flow and surface waterquality change.

BetaLine is a compact UV system, equipped with unique high-efficient low-pressure UV lamps. They operate in automatic mode on the most economic lamp power due to bestUV’s intelligent power controlsystem. The bestUV system runs exactly on the power needed to fulfill minimum UV dose requirements, even when flow and surface waterquality change.

Compared to medium-pressure (MP) UV systems the BetaLine is saving a lot of energy and has thus the lowest carbon footprint, which fit into the ‘environmental phylosophy’ of the waterworks.

The engineers selected bestUV systems for a couple of reasons:

- lowest investment costs,

- 15 years lifecycle costs calculation (LCC),

- long lamp life, 3x more compared to medium-pressure UV lamps

- easy installation and maintenance,

- automatic lamppower controlsystem, resulting in minimum use of energy,

- automatic cleaning device, included in Önorm validation tests,

- proven reliability at many drinking water references.

Again bestUV systems are disinfecting drinking water for human consumption against lowest costs on a very environmental friendly way and thus preserve and protect the beautiful nature.

For more information contact the ‘experts in ultraviolet light’.

Several bestUV systems were installed in one of the latest new-built aquaparcs in Europe. The new constructed aquaparc is officially opened in the begin of 2012.

Several bestUV systems were installed in one of the latest new-built aquaparcs in Europe. The new constructed aquaparc is officially opened in the begin of 2012. Dutch UV manufacturer bestUV was selected to deliver NIPH (Norwegian Institute of Public Health) approved KappaLine UV systems to be installed on a ‘semi-submersible’ accommodation platform or ‘hotel on sea’.

Dutch UV manufacturer bestUV was selected to deliver NIPH (Norwegian Institute of Public Health) approved KappaLine UV systems to be installed on a ‘semi-submersible’ accommodation platform or ‘hotel on sea’.  The Dutch manufacturer bestUV presented a new generation of high efficiency ultraviolet (UV) systems called KappaLine UV at the Aquatech tradeshow. The range is specifically designed, microbiologically tested and certified for the disinfection of drinking and process water. The KappaLine UV product range is officially approved for disinfection of (drinking) water.

The Dutch manufacturer bestUV presented a new generation of high efficiency ultraviolet (UV) systems called KappaLine UV at the Aquatech tradeshow. The range is specifically designed, microbiologically tested and certified for the disinfection of drinking and process water. The KappaLine UV product range is officially approved for disinfection of (drinking) water. bestUV is proudly based in the world’s most intelligent region. Brainport Eindhoven, the industrial high-tech heart of the Netherlands, was named ICF’s Intelligent Community of the Year for 2011.Top technology region Brainport is a breeding ground for innovation and the home base for leading companies like bestUV, world-class knowledge and research institutes. Thanks to unique high-tech cooperations, bestUV is able to innovate, invent, manufacture and sell ‘state-of-the-art’ high-tech UV systems. Download the Brainport brochure

bestUV is proudly based in the world’s most intelligent region. Brainport Eindhoven, the industrial high-tech heart of the Netherlands, was named ICF’s Intelligent Community of the Year for 2011.Top technology region Brainport is a breeding ground for innovation and the home base for leading companies like bestUV, world-class knowledge and research institutes. Thanks to unique high-tech cooperations, bestUV is able to innovate, invent, manufacture and sell ‘state-of-the-art’ high-tech UV systems. Download the Brainport brochure